- Reduced variability during sample preparation

- Radically improved sample yield

- Cryo-EM实验室中工作流的效率提高

体外

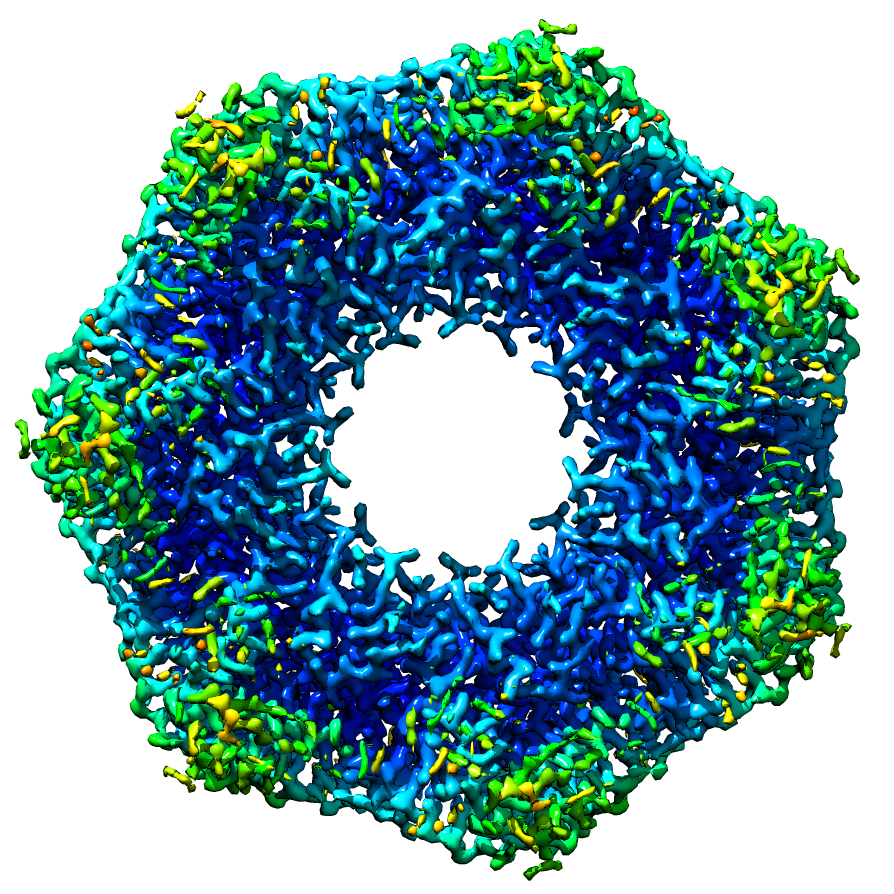

Reproducible and Reliable Sample Preparation for single particle analysis

Benefits of the VitroJet:

- Automation for standardizing sample preparation

- Ethane jetting for making vitreous samples with amorphous ice every time

- Blotless technology with consistent and customizable ice thicknesses

- Compatible with multiple grid types

- Pin-printing technology for consistent material deposition onto the grid

- Dew point controlled – no evaporation or condensation after deposition

- 内置血浆清洁剂,以保持网格的一致性

- No dry room required

The VitroJet is a automated solution that aids CryoEM researchers by removing the variability that’s typically associated with sample prep and provides users with a method that is consistent and reproducible. Using pin-printing technology with sub-nanoliter volume sample deposition, and ethane jetting for vitrification, the VitroJet substantially reduces waste and ensures quality samples with customizable ice thickness on every grid.

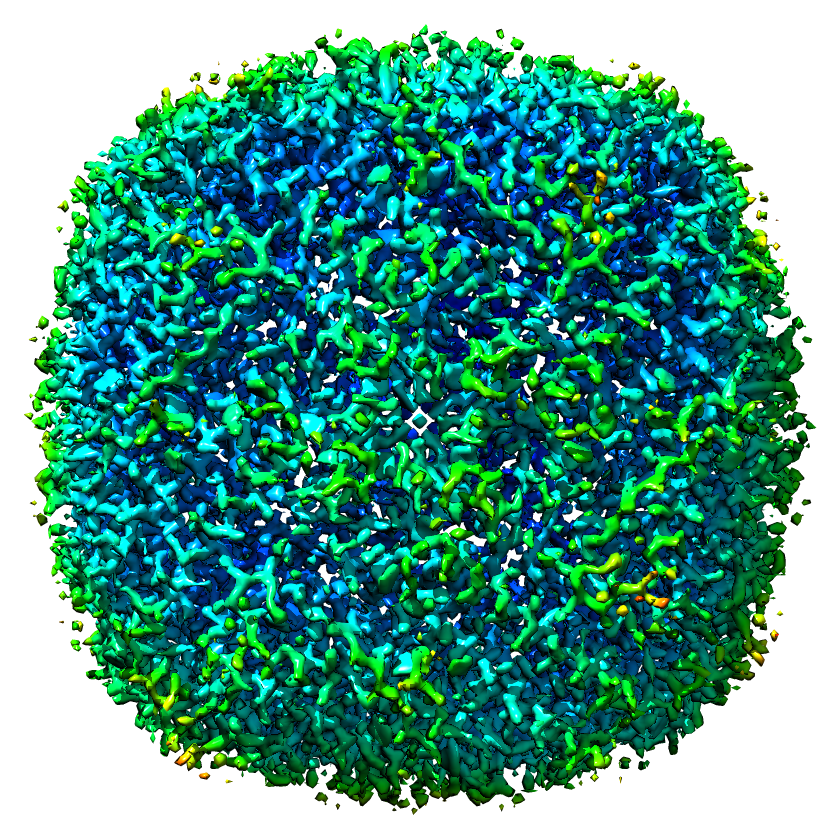

CERES ICE DEFENSE SYSTEM

减少污染并最大化冷冻的薄片产量

流星

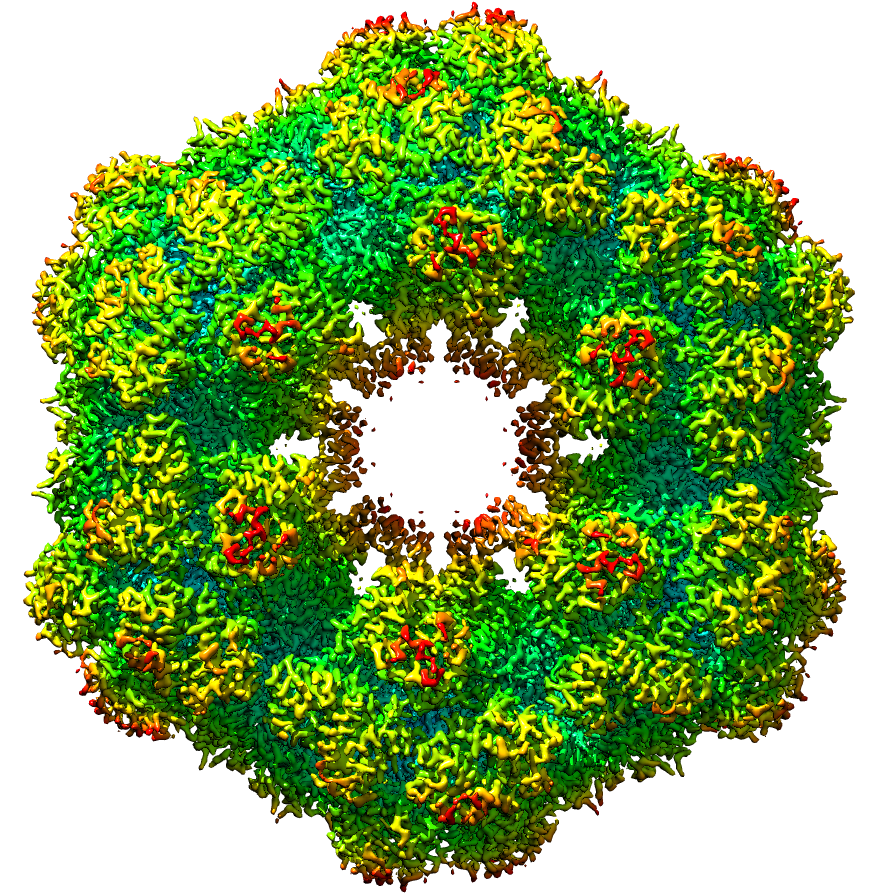

Instant CLEM with guided milling to maximize ROI’sin final lamella

- Three-fold improvement in sample yield thanks to Z-stacking and deconvolution for targeted z-plane milling

- Upgrade for Aquilos 1 & 2 Microscopes as well as Zeiss, Tescan, and JEOL FIB-SEMs

- In-situ design for simplified correlation of EM and LM micrographs and post-milling sample verification

- Multiple high NA objective (up to 0.9 NA) and sensitive camera (up to 95% QE) options for the widest variety of fluorescence based experiments

Cryo-ET provides users with an excellent opportunity to view proteins and complexes in-situ but identifying these areas within a large volume is very difficult. A reliable method for locating and targeting regions of interest (ROI’s) is necessary to increase throughput and efficiently mill lamellae. Additionally, higher numbers of lamella are often needed to create higher resolution 3D reconstructions. these fluorescence-containing lamellae, a is necessary. The METEOR is an in-situ fluorescence light microscope that can be integrated to a cryo-FIB to identify and verify region of interest during and after milling. The METEOR is an elegant retrofit to microscopes like the Aquilos 1 and 2. It’s also compatible with FIB-SEMs from JEOL, Tescan, and Zeiss.